What is the main Purpose & Procedure of Preventive Maintenance?

The purpose of preventive maintenance means periodic service work performed on a vehicle that will help keep it functioning correctly for a long time.

All vehicle manufacturers publish a list of service work to be performed regular basis.

The procedure of the Preventive maintenance program is also called routine maintenance because it is usually performed on a set schedule routine.

The interval specified for Preventive maintenance once is often expressed in the time and miles(km) such as:-

- Every six month’s (could be longer for many vehicles)

- Every 5,000 to 10,000 km depending on the vehicle and how it is being operated

- Either of the above, whichever occurs first

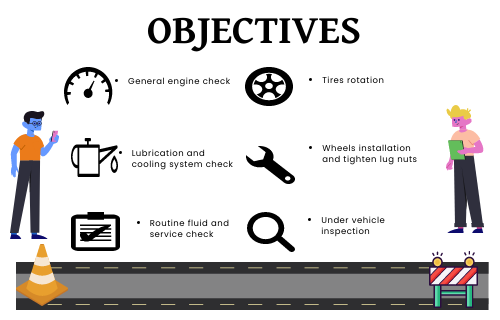

The most common preventive maintenance flow chart is below

- General engine check

- Lubrication and cooling system check

- Routine fluid and service check

- Tires rotation

- Wheels installation and tighten lug nuts

- Under vehicle inspection

The procedure of the preventive maintenance checklist below

- Engine oil and oil filter replacement

- Air and cabin filter replacement

- Tire inflation pressure check, inspect & rotation

- Brake and suspension system inspection

- Underhood inspection and fluid check

- Under vehicle inspection and fluid check

- Air conditioning system inspection and service

- A safety inspection, such as all lights & windshield wiper blades

- Routine cleaning of the vehicle both inside & outside

What is a pre-service inspection?

Pre-service inspection is prior to any service work, it is wise to check the vehicle for damage and document the work order if any damage is found in most dealerships and shops, this is the responsibility of the following person.

- Service adviser(service writer) or

- Shop foreman or

- Shop owner

The nominee must inspect the vehicle for the following

- Body damage

- Missing wheel covers

- Glass damage such as a cracked windshield

- Any faults in the point or trim

- Valid license plates

Protect the vehicle

Before much work is done, protect the interior of the car by using a protective plastic or paper protector in the following areas.

- Seats

- Floor

- Steering wheel

What is a safety inspection?

Safety inspections are usually recommended to be done whenever the car is in the store for repairs or repairs.

The following safety inspections are recommended before service

- Headlights (high & low beam)

- Taillights

- Turn signals

- License plate light

- Parking light

- Horn

- Windshield wiper operation

- Mirrors

- Defroster fan operation

- Steering for excessive looseness or leaks

- Shock absorbers that allow excessive body sway

- Tire condition, tread depth & proper inflation pressure

- Parking brake operation

- Exhaust system for excessive noise or leaks

Windshield wiper & washer fluid service

Windshield wipers

- The wiper blades are made of rubber and tend to be brittle due to age

- Wiper blades should be cleaned whenever the car is cleaned with water and a soft cloth

Wipe blade or wiper blade insert replacement includes the following steps:-

- Turn the ignition switch to on (run)

- Turn on the wiper switch and use the wipers

- When the wipers are in an easily accessible position, turn off the ignition wipers should stop

- Delete entries or all fields such as service information and/or instructions on the changeable wiper blade pack

- Turn off the wiper button and allow the wipers to reach the park checkpoint for proper operation

- After double-checking that the wiper is securely attached, turn on the heat button (run)

Windshield washer fluid

- Windshield washer fluid level should be checked regularly and refilled as necessary

- Use only the fluid that is recommended for use in the vehicle windshield washer system

- Most windshield washer fluid looks like Blue Water

- It is actually water with an alcohol (methanol) additive to prevent freezing and to help clean the windshield by dissolving bugs

- Be careful not to spill any washer fluid when feeling the Reservoir because the corrosiveness can harm wiring and electronic components

Cabin filter replacement

- A cabin filter is used in the heating ventilation and air conditioning(HVAC) system to filter the outside air drawn into the passenger compartment

- Some filter contains activated charcoal to help eliminated orders

- The Cabin air filter should be replaced after every year or every 20,000 km

- The Cabin air filter can be the seed from Under the Hood at the cowl (bulkhead) or

- Under the dash usually behind the globe (instrument panel) compartment (check service information for the exact location and servicing procedure for the vehicle being serviced)

Air filter inspection/replacement

- Air filter filters air pollution before entering the engine inlet system

- The air filter should be replaced according to the vehicle manufacturer recommendation

- Over time the filter will start to get clogged and decrease the engine efficiency

- Many vehicle manufacturers recommended replacing the air filter every 40,000 km or more frequently under dusty conditions

- Many service technicians recommended replacing the air filter every year

Brake fluid inspection

Brake fluid level

- Brake fluid is used to transmit the force of the driver’s foot on the brake pedal called the service break to each individual will break

- The brake fluid should be checked at the same time the engine oil is changed or every 6 months whichever occurs first

- It is normal for the brake fluid level to drop as disc brake pads wear

Where the fluid level is still low for two possible causes

- Cause 1 Normal disc brake pad wear (inspect the brake if the fluid level is low)

- Cause 2 A leak somewhere in the hydraulic brake system (carefully inspect the entire brake system for a leak if the brake are not worn and the brake fluid level is low)

- Cause 3 Do not overfill a brake master cylinder (the brake fluid gets hotter as the brakes are used and there must be room in the master cylinder reservoir for the brake fluid to expand)

Types of brake Fluids

- Brake fluid is made from a combination of various type of glycol a nonpetroleum based fluid

- Brake fluid is a poly-alkaline-glycol-ether mixture called poly-glycol for short

- All poly-glycol brake fluid is clear to amber in color

- The Automotive Engineers Association (SAE) and the Department of Transport (DOT) have established specificity standards for brake fluids

DOT 3

- The dot 3 brake fluid is most often used it observed moisture and according to SAE and observed 2% of its volume in water per year

- Moisture absorbs fluid from the brakes through small parts of the brake system and adjacent markers

- Over time the water will corrode the system and thicken the brake fluid

- Moisture can cause sponge breakage because the increase in water inside the boils at low temperatures can lead to the formation of steam

- DOT 3 Must be used for a sealed (capped) container

- If allowed to remain open for any length of time, DOT 3 will absorb moisture from the surrounding air

DOT 4

- The DOT 4 Brake fluid is formulated for use by all vehicle imported or domestic

- It is commonly called low moisture absorption(LMA) because it does not observe water as fast as DOT 3

- It is still sensitive to moisture and should only be used in a sealed container

- The cost of DOT 4 is almost double the cost of DOT 3

DOT 5

- DOT 5 type is commonly called silicone brake fluid

- It is made from polydimethylsiloxane

- Because it does not absorb water it is called nonhygroscopic

- DOT 5 Brake fluid is not compatible and should not be used with DOT 3 or DOT 4 brake fluid

- DOT 5 Brake fluid is purple (violet), separating it from DOT 3 or DOT 4 brake fluid

DOT 5.1

- The DOT 5.1 Brake fluid is a nonsilicone based poly-glycol fluid that is clear to amber in color

- This server duty fluid has a boiling point of over 500°F (260°C) equals to the boiling point of silicone-based DOT 5

- Fluid, unlike DOT5, the DOT 5.1 Fluid can be mixed with either DOT 3 or DOT 4 according to the brake fluid manufacturer recommendation

How can test brake fluid?

- With visual inspection check the color of the brake fluid

- It should be clear or almost clear

- If it is dark brown or black it should be replaced

- With the boiling point, a boiling point of brake fluid can be tested using a handheld tester

- Follow the instructions that come with the inspector

Engine oil inspection

- The oil level should be checked when the vehicle is parked in a higher position and after the engine has been switched off for at least several minutes

- The oil level indicator is commonly called a dipstick is clearly marked and in a convenient location

- To check the oil remove the dipstick wipe off the oil and Reinsert it all the way down

- Also, remove the dip and check where the oil level affects the indicator

- If oil needs to be added use the specified oil and add to the engine through the oil fill opening

Engine oil change interval

- Most automotive experts recommended that the engine oil be replaced and a new oil filter installed every 10,000 km or every 12 month whichever occurs first

- Most vehicle since the early 2000s have used an oil live monitor system to notify the driver when the engine oil should be changed

- The oil life monitoring will light a dash lamp when the oil needs to be changed

Engine cooling system

- The cooling rate in a cooling rescue tank or explosion tank

- The front of the radiator should be carefully infection and clean of bugs, dirt, or mud that can often restrict airflow

- Maintenance should also include a visual inspection for a sign of coolant system leaks and for the condition of the coolant hoses and accessory drive belts

How can test coolant with a visual inspection?

- Coolant should be clean and close to the color when it was new

- The milk-colored cooler is an oil indicator in a system that can be caused by an inefficient engine gasket

- If the coolant is dark or muddy looking it should be replaced

Automatic transmission fluid check

- The automatic transmission fluid (ATF) is another important fluid that should be checked regularly most automatic transmission fluid levels should be checked under the following conditions

- The car must be parked in the same place

- Transmission fluid should be at room temperature this may require the car to be driven for many miles before the temperature can be checked.

- The engine should be running with transmission in neutral or Park as specified by the vehicle manufacturer

To check the performance of fluid of automatic transmission follows these terms:-

- Start the engine and moves the gear selector to all gear position and return to the park or neutral as specified by the vehicle manufacturer

- Remove the transmission/transaxle dipstick (fluid level indicator) and wipe it off using a clean cloth

- Reinsert the dipstick until fully seated removed the dipstick again and not the level

Do not overfill any automatic transmission/ transaxle

- Even if just 100ml too much were added by mistake, could cause the fluid to foam

- This frothy liquid cannot soften enough or use compression muscles that make the unit work better.

The smell of automatic transmission on the dipstick

- If it seems burned or rancid further service of the automatic transmission transaxle will be necessary

look at the color of the fluid

- It should be red or light brown

- A dark brown or black color indicates oxidation usually caused by too high operating temperature

- further service and diagnosis of the automatic transmission/transaxle will be required

Power steering fluid checking process

- Check the level of fluid running outside the engine

- The cap for the power steering reservoir is marked with an icon of a steering wheel or the wards power steering

- Remove the cap by twisting it counter-clockwise and use the level indicator as part of the cap to determine the level

Accessories drive belt inspection

- In V-type belts (so named because of their shape) are 34° at the “V”

- The pulley they ride through is generally 36°

- This 2° difference result in a wedging action and makes power transmission possible, but it is also the reason why V-belts must be closely infected

- It is generally recommended that all belts, including the serpentine (or poly v) belts, be replaced every 4 to 7 years

- When the belt that turns the water pump breaks the engine can get very hot causing serious engine damage and if one belt breaks it often creates other belts to become too tangled causing them to break

Tire and wheel service

Inflation pressure

- Tire pressure should be checked when the tires are cold

- As a vehicle is driven the flexing of the tire and friction between the tire and the road causes an increase in temperature

How to check tire pressure?

- Use of good quality tire pressure gauge and push it against the tire valve stem after removing the cap

- Be sure no air escapes when the pressure gauge is used as this will cause an inaccurate reading

- Compare the pressure reading with the specified tire pressure

- The specified pressure is located on a placard attached to the driver’s door or door post or in the glove compartment

Inspection of tire

- All tires should be carefully inspected for faults in the tire itself or for signs that the steering or suspension system of the vehicle

- Tread depth (2/32 of an inch as the standard minimum allowable thread depth in most States)

- Unequal wear

- Cuts in the tread or sidewall

- Bulges for uneven sidewalls

What is a tire rotation?

To assure long life and even tire wear, it is important to rotate each tire to another location it’s called tire rotation.

Differential fluid check

Procedure for checking

Rear-wheel driver vehicles use a differential in the rear of the vehicle to change the direction of power flow from the engine to the rear wheels.

To check the performance of differential fluid following this step:-

- Step 1 Hoist the vehicle safety

- Step 2 Visually check for any signs of leakage

- Step 3 Remove the inspection plug from the side or rear cover of the differential assembly

- Step 4 Insert your small finger into the hole in the housing and then remove your finger

Type of differential lubricants

Differential lubes are specified by the American Petroleum Institute (API), the most differential engine required

- SAE 80 W-90 GL-5

- SAE 75 W-90 GL-5

- SAE 80 W GL

Manual transmission/transaxle fluid check

Check the performance of manual transmission fluid

- Hoist the vehicle safety

- Find the transfer/test plug (fill) plug touch the factory service manual to find the appropriate plug to remove the fluid level

Under vehicle inspection

Visual inspection

- In preventive maintenance procedure, the Other items under the car that may need to be checked or lubricated include

- Shock absorbers and springs

- Transmission/transaxle shift linkage (check the service manual for the correct lubricant to use)

- Exhaust system including all pipes and hangers

- Brake lines for evidence of damage or leakage

- Shock absorbers for leakage or damage mounts

- Directing the connection to the open relief or damaged or missing parts

- Parking brake cable guides

We hope readers can understand this “Procedure of Preventive Maintenance in Automobile Industry” article and basic fundamentals PM checklist.

CARSUFFER.COM

FAQ About Preventive Maintenance Of Automobile Industry

What is the maintenance goal?

The purpose of maintenance is to ensure the optimal performance and availability of production equipment, equipment, and related services at a reasonable cost and under reasonable conditions of quality, safety, and environmental protection.

To protect the car why the procedure of preventive maintenance is important?

Always procedure of preventive maintenance with Safety harnesses is designed to minimize the risk of collapse and to increase the vehicle’s rest time. Other common examples of safety care include oil replacement, spark plug testing, plumbing testing, and filtering, as well as careful inspection of the car’s abdomen, brakes, and overall engine health.

What are the 4 types of procedures of preventive maintenance?

Four common types of nutrition philosophies can be identified, namely remediation, prevention, risk-based and conditional care.

What are examples of preventive maintenance?

For example: performing regular business and equipment inspections, cleaning and lubricating essential equipment, and tidying your business’s grounds are all examples of preventive maintenance. The preventive maintenance policy is to prevent mechanical failure before it occurs and to reduce the risk of accidents.

Read this:- How To Brake Fluid Change By Your Self – With Picture

Read this:- Best Tyre Brands In The World You know This In [2021]

Visit site:- www.carsuffer.com

Comments on “The procedure of Preventive Maintenance in Automobile Industry”