Hello and welcome back to Carsuffer, after long today we describe AUTOMOBILE OPTIONAL FITTINGS (AOF). Optional Part give in below and we discuss each and every part, So be with us and share this knowledge with everyone.

- Transfer case

- Power take-off box

- Air compressor

- Front axle drive

- Tractor truck fifth wheel coupling

- Winch

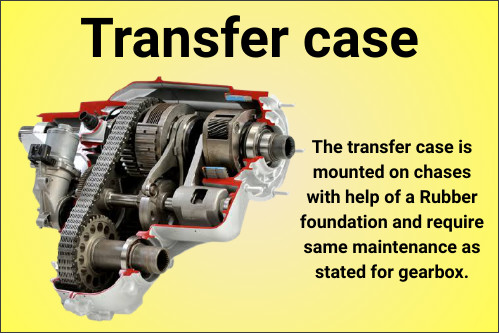

1. Transfer case (AOF)

The first Automobile Optional Fittings (AOF) The transfer case is a small gearbox attached to the main gearbox in a vehicle where power is to be taken for:-

- To drive front wheels.

- To drive winch for pulling stuck-up vehicle or any other object.

- To provide drive to truck-mounted Crane.

- To provide drive to truck-mounted generator set or any other machinery.

As stated above it is a small gearbox transfer case where its input flange gets its drive from the main gearbox with the propeller shaft.

This transfer case has two output shafts the one fitted at the rear is connected to the rear axle through the rear propeller shaft and the other one is fitted to the front axle differential with the help of the front propeller shaft.

The transfer case is mounted on chases with help of a Rubber foundation and requires the same maintenance as stated for the gearbox.

It has one gear lever which engages the gear when required now let us discuss the working of the same.

A transfer box is your input flange a is coupled to the output flange of the main gearbox with the help of a propeller shaft.

It has two gears 1 and 2 places on it these gears are free on the shaft and R in constant mesh with gear 3 and does of countershaft which runs on to ball-bearing fitted another site of the shaft is the housing.

Gear 4 is again in constant mesh with gear 5 of the output shaft working for giving drive to the rear propeller shaft.

2. Power take-off box (AOF)

It is a small gearbox fitted on the opening of the inspection cover of the main gearbox input care is always in mesh with one of the Layshaft gears as such it runs as long as the engine is running (clutch pedal not pressed).

This gear can be meshed to give the input double gear by the fork and gear lever. When it is brought to mesh with the input the shaft rotates. Such power take of boxes is usually known as P.T.O. boxes.

These are used for driving small units such as separate air compressors, hydraulic pumps, used in tipping trucks and winches, etc.

Please note Power take-off box boxes are designed to transmit power from 3 horsepower to 5 horsepower.

3. Air compressor (AOF)

In the olden days when air pressure for inflating tires was not readily available, the air compressor was a standard fitting on most trucks and buses but now when air pressure for tire inflators is available even in villages air compressors have become absolute in motor transport.

However, this is being supplied in some practices such as HMT zetor is a standard fitting.

Usually, the air compressor was attached to the gearbox on its inspection housing as in the case of power take-off in this case Institute of power take-off shaft crankshaft is heated and on top of the housing, the compressor block is fitted.

Now a day in vehicles where error pressure brakes are employed compressor is usually driven from the camshaft as in a Tata vehicle where a separate air bottle with tire inflator tube connection is provided while in another type of vehicle.

Such as the Leyland truck’s separate compressor unit is fixed in line with the injection pump and gets its drive from the injection pump drive shaft.

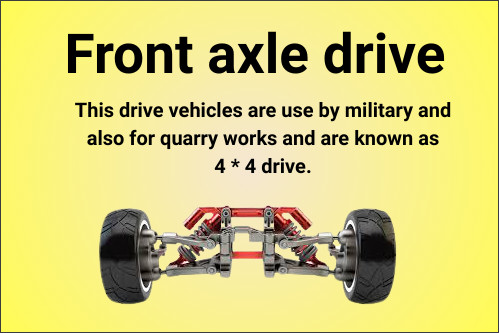

4. Front axle drive (AOF)

The front axle is also a drive axle for such vehicles which are used in sendy our slushy soil or have to be used where there are no roads.

Such vehicles are usually utilized by the military and also for quarry works and are known as 4 * 4 drive.

You must have seen a military Jeep where the drive can be given to front Excel also as and when required.

We have learned that the front axle is also a steering axle and their vehicle is started by moving the stub axle mounted on the kingpin.

In such a vehicle where the front axle is also used as a drive axle the drive to, the hub is given with the help of the propeller shaft and constant velocity joints, and this complete unit is a house in a bald and union joint where having print top and bottom.

This axle requires special attention as far as maintenance is concerned and has to be regularly greased and serviced.

In case of slightest where in the bushes or bearing of kingpin it will cause wheel wobbling.

Bushes should be replaced immediately when we wear is notice and if the bearing is fitted this should be adjusted by removing or adding shims under the bearing cap.

5. Tractor truck fifth wheel coupling (AOF)

In our earlier article while introducing the type of vehicle we had made mentioned articulated trailer and tractor.

Such types of vehicles are becoming very popular nowadays as the load-carrying capacity of the vehicle increases considerably.

You must have seen such a vehicle applied by D.T.C. as well as huge oil tankers and platform trailers.

Lets us study how it is coupled to the trailer the coupling used in this case is known as fifth wheel coupling.

The fifth wheel coupling consists of supporting plate balance with what’s a turntable and a locking mechanism.

Over and above this a safety strip is also provided to prevent accidental uncoupling of the trailer.

To couple the semi-trailer to the tractor process as follows:-

Shift aside the safety stripe and move the control handle forward back the tractor carefully so that the kingpin of the semi-trailer came to snaps into coupling locks the two vehicles will be automatically (locked) coupled.

Once again ensure that the safety stripe is in the lock position lift the parking lake and locket in the uppermost position and release the semi-trailer parking brakes semi-trailer is fully coupled and ready to go.

For the uncoupling process under:-

Apply semi-trailer parking brakes to lower the parking legs and lock the same in the lowermost position shift inside the safety strip.

Move the coupling control handle to the foremost position and drive out the tractor for what slowly and carefully.

6. Winch (AOF)

The last Automobile Optional fittings (AOF) are the winch, some of the trucks, 4*4, and station wagons are equipped with a winch installed at the front hand over the front bumper.

The winch is usually used to pull out blocked vehicles or recover vehicles for lifting Loads.

The engine power is transmitted to The Winch via gearbox either through transfer gearbox or through power take-off box and a propeller shaft with to universal joint.

At the winch is fitted a worm wheel which gets its drive from warm run by the propeller shaft.

On the worn, the shaft is also created an external contracting type of brake which is used for holding the lord for control and winding of drum on which Steel rope is wound.

The drum-shaped is coupled to the form will shaft with help of a dogg clutch operative through a Lever.

While operating the winch the man gearbox is set in a neutral position and the vehicle breaks sometimes to be on the safer side wooden villages are also placed before Tyres to lock the same.

FAQs

- How much oil is stored in the transfer case of Tata Safari Storme?

Capacity: 1.2-1.4 litre

- What is power take-off?

A Small Gear Box.

- What is the use of a winch?

It is used to pull out the entrapped vehicle.

- What is the main specification of four-wheel-drive vehicles?

Driven is given to all four wheels.

- What are called automobile optional fittings?

The most useful and advanced parts or machines that can be fitted in an automobile are called automobile optional fittings.

Read this:- Automobile Chassis and Body Engineering Knowledge

Visit site:- www.carsuffer.com

Comment on “AUTOMOBILE OPTIONAL FITTINGS (AOF)”