- What is a 2-Stroke Petrol Engine?

- Who Invented of 2-Stroke Engine?

- Working Cycle of 2-Stroke Petrol Engine

- The Reason for 2-Stroke Petrol Engine not Producing 2X Horsepower

- Comparison between 4- STROKE ENGINE & 2- STROKE ENGINE

What is a 2-Stroke Petrol Engine?

A 2-Stroke Petrol Engine is a type of internal combustible engine that fills the power cycle with two-piston blades during only one crankshaft regime.

This compares with a stroke engine that requires four-piston blows to complete the power cycle during two crankshaft shifts.

2-stroke petrol engines have a thing happen with the cylinder at bottom dead center.

Exhaust gas is pushed out of the cylinder by intake air, which is actively pumped into the cylinder.

This is called scavenging a 2-stroke petrol engine.

In the previous article, we have studied that in 4-stroke petrol engine four times traveling of piston up and down.

There is only one power stroke rest are ideal strokes and do not produce any power.

To reduce the number of Ideal strokes in a 2-stroke engine was invented in which complete operation induction compressor power and exhaust is completed in 2-stroke.

When moving the Piston Once Up and once down or in one revolution of the crankshaft, theoretically, the 2-stroke engine should produce and double the Horse Power in the same size of the engine then 4-stroke engine cycle.

Who Invented of 2-Stroke Engine?

“Mr. Dugad Clark” invented it in the year 1880. A 2-stroke cycle engine is also called a “Clark cycle engine”.

Working Cycle of 2-Stroke Petrol Engine

In the previous article, we have studied that all the four operations induction, compression, power, and exhaust are completed in into stroke the one revolution of the crankshaft.

In other words, every time piston comes down from TDC to BDC there is a power stroke now let’s study how it works.

In small engines, exhaust and inlet ports are made in the cylinder liner.

When the Piston comes down from TDC to BDC in power stroke it opens the exhaust port which is made at a lower portion of the liner.

Due to uncovering of Port by Piston, the exhaust gases escape out through the port.

The Piston travels down a little more is it also and covers the inlet port which is usually made opposite to the exhaust port.

Due to uncovering of the inlet Port by the Piston fresh charge find its way in the cylinder the piston of the pot and the working of the 2-stroke cycle engine.

As such, we had seen that when the piston is reaching BDC both the operation induction and exhaust are completed in one stroke.

Now when the Piston travels up from BDC to TDC it covers both the inlet and exhaust of the port and the charge which had found its way in-cylinder gets trapped and starts getting pressed the commencement of compression stroke.

when the piston reaches TDC the charge gases expand spontaneously causing the piston head making it moves down with force.

The Piston moves down with force from TDC to BDC after the charge is ignited it is known as the power stroke.

When the piston is at the piston skirt and covers the port in the cylinder liner from where the fresh charge finds its way from the manifold to the crankcase due to the partial vacuum created by the crankshaft.

And its weight and when the Piston starts moving down in power stroke the charge which has come in the crankcase is press by crank weight to the inlet port side ready for being taken to the cylinder in this way the complete cycle works.

The Piston used in this type of two-stroke engine is dome type up the slope in the piston is given in such a way that deflects the incoming charges to word top and the slope on the other side deflects the exhaust gases to get out from the exhaust port.

In case it was a fault head Piston then the incoming charge will find its way out through the exhaust port resulting in loss of power and more fuel consumption.

You have seen that mixture of petrol and air called charge in first slightly compress in the crankcase and then it finds its way to the cylinder.

As such it is not possible to keep lubrication oil in the sum for lubrication of crankshaft but all such parts namely crankshaft main, big end bearings, gudgeon pin, cylinder liner have to be lubricated otherwise the engine will seize.

To lubricate all such parts certain percentage of lubricating oil which is about 4 to 5% of petrol is a mix as such when the charge gets into the crankcase.

The lubricating oil present in the charge lubricates the main big end bearing of crankshaft gudgeon pin bush connecting rod small and Piston skirt and liner.

We have just studied the working of the two-stroke engine wherein it was explained that every time piston travel from TDC to BDC there is power stroke or in other words, it has twice the power strokes than the size of the name of 4 stroke engine

It means that two-stroke engines have Double the number of power strokes than the four-stroke engine should produce double the horsepower than 4 stroke engine of the same size but in actual practice, it is not so.

It only produces 20 to 40% more horsepower than 4 stroke engines of the same size.

The Reason for 2-Stroke Petrol Engine not Producing 2X Horsepower

(A) When the Piston reaches BDC at the end of the power stroke both the inlet and exhaust ports are open irrespective of giving slope in the Dome type of piston used in such engine a certain amount of fresh charge escapes out along with exhaust gas.

(B) As the inlet port remains open for a short time as compared to the 4-stroke engine as such due to the short timeless quantity of charge can find its way in the current case.

Due to the above stated to the main reason the two-stroke engine does not develop double horsepower than the 4-stroke engine of the same size.

This type of engine being light in weight and giving more power than 4 stroke engines is mostly used for mopeds, motorcycles, scooters, motorboats, and many other small portable machines.

In big engines to increase their efficiency superchargers are used for filling charge in the cylinder in such cases the charge is not routed through the crankcase, the supercharger is connected directly to the intake port.

Such engines give more power than the port type of engines whereas in some other makes of engines instead of providing exhaust port of the cylinder wall exhaust valve are provided.

Comparison between 4- STROKE ENGINE & 2- STROKE ENGINE

| ★ | 4- STROKE ENGINE | ★ | 2- STROKE ENGINE |

| 1. | It gives one power Stroke in four-stroke in two revolutions of crankshaft since three-stroke are ideal strokes. | 1. | Power stroke takes place in every two strokes one power stroke for one revolution of the crankshaft. |

| 2. | Due to more ideal strokes and non-uniform load on the crankshaft heavier flywheel is required. | 2. | The engine has a more uniform load as every time Piston comes down it has a power stroke as such a light flywheel is necessary. |

| 3. | The engine has more parts such as valves and its operating mechanism engines are heavier. | 3. | The engine has no valve and their operating mechanism these are light in weight. |

| 4. | The engine is costlier as it has more parts fitted in it. | 4. | The engine is cheap as it has fewer parts. |

| 5. | Engine efficiency is more as charge gets completely burnt fuel consumption is less. | 5. | Efficiency is lower if some parts of the charge get escaped through the exhaust port with this field collection is more. |

| 6. | The engine while working makes a list sound as part of the sound gets damp due to the water jacket around it. | 6. | Mostly the engines are air-cooled and there is no damping off the sound as search engines produce more sound. |

| 7. | The engine gives clean exhaust as the charge gets completely burnt. | 7. | Due to less time available for the burning of charge, some of the environmental charges get escaped through which exhaust port giving smoke. |

| 8. | An engine requires more space. | 8. | The engine is compact in size. |

| 9. | Lubricating oil consumption is less as the soil gets recirculated. | 9. | Lubricating oil is mixed in the fuel and gets burnt in the consumption chamber oil consumption is more. |

| 10. | The engine is best suitable for vehicle and stationary applications as its running cost is less. | 10. | The engine is more suitable where weight consideration is a deciding factor such as Marine engine lawn mower motorcycle and two-wheelers. |

| 11. | Due to more moving parts, friction losses are more its mechanical efficiency is less. | 11. | Due to fewer moving parts, mechanical efficiency is more. |

| 12. | Decarbonizing is required after a long time. | 12. | The engine requires decarbonizing frequently. |

We hope readers can understand this “What is 2-Stroke Petrol Engine, & Working of 2-Stroke Petrol Engine“ article and basic fundamentals of an automotive engine.

CARSUFFER.COM

FAQ about 2-Stroke Petrol Engine

What is the machine called which converts heat energy into mechanical work?

Engine.

What are those engines called in which fuel burns outside?

External combustion engine.

How much degree power overlaps in a six-cylinder engine?

25°C

What is another name for the 2-stroke engine?

Clark cycle engine.

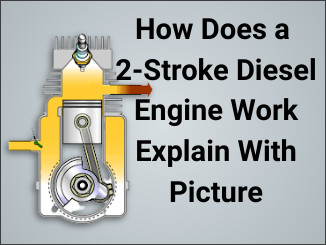

Read this:- How Does a 2-Stroke Diesel Engine Work Explain With Picture

Read this:- What is 4-Stroke Petrol Engine & Working of 4-Stroke Petrol Engine

Read this:- 4-Stroke Diesel Engine Diagram Explain With Pictures

Visit site:- www.carsuffer.com

Comments on “2-Stroke Petrol Engine Working Cycle & Comparison [2022]”